CELLAR

After the 2010 earthquake, we reused a wall from one of the oldest wineries in the area. We wanted to preserve that part of history, taking it with us to our barrel room. Its material provides excellent insulation against the extreme temperatures we tend to get in the valley.

Construction of the winery

As part of this new challenge, we wanted to build a winery using recycled materials and taking advantage of spaces that already existed in the countryside.

As part of this new challenge, we wanted to build a winery using recycled materials and taking advantage of spaces that already existed in the countryside.

View the image gallery for the winery construction →

The Winery

The insulating properties of adobe make it ideal for the conservation and ageing of our wines.

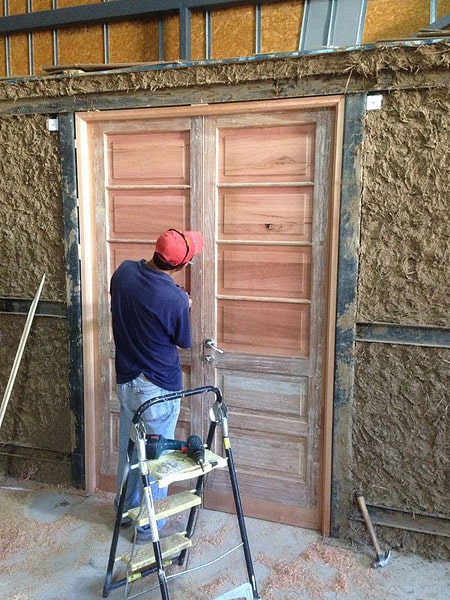

The structure of the winery is supported by repurposed iron, and the main door, which is made from the native raulí wood, was recovered from a demolition site and restored by an experienced local craftsman to recover and enhance its natural beauty.

The winery is equipped with water, LED lighting and an air conditioning system, which ensures the optimal temperature for each stage of winemaking.

View the image gallery of the winery→

Destemming

In the beginning, we made use of an ancient technique, typical of the countryside, where each variety was destemmed by 8 workers using a zaranda, a structure of posts or poles made from Chilean bamboo tied together with hemp. It was a special task, carried out on cold mornings after hand-harvesting the grapes. But it became a thing of the past in 2016 when we brought in technology that allows us to carry out the process in the same way but in less time. We are therefore able to make sure that the most important work of the vineyard is carried out properly and the grapes arrive at the winery in the best condition.

View the destemming image gallery →

Pressing

All of our pressing is done manually, and we are both present during this process. It is slow and hard work, but every day we become more passionate about the results. Our press has been with us almost since the beginning, and every year we can see the quality of the juice it produces, suitable for use in every wine blend we make. It presses delicately without over-extracting, making a definite contribution to our wines and every year we realize what a boon it is.

View the image gallery for our pressing process →

Vinification

Around 95% of our wine is fermented with native yeasts, in plastic bins with manual pump-overs and punch-downs. We are aiming for low levels of extraction, preserving the essence of the place, and so we avoid intervening too much in the processes. Our fermentations take between 20 and 25 days, and then the wine is gravity-fed into barrels that vary between new and fourth-use.

View the vinification image gallery →